Get a Quote & Support

Our stainless steel tubing team specializes in delivering high-quality, precision-engineered tubing solutions tailored to meet the diverse needs of industries worldwide.

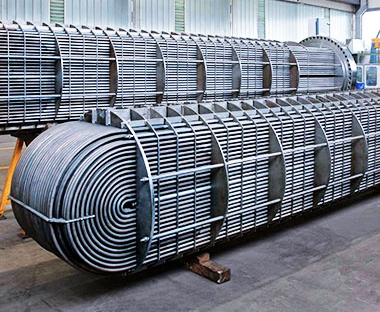

JIS G3463 Stainless Steel Tubing

JIS G3463 is a Japanese Industrial Standard that specifies the requirements for stainless steel pipes used in boiler and heat exchanger applications. It covers seamless and welded austenitic stainless steel tubes designed for high-temperature and corrosive environments.

- International Standard :

- Stainless Steel Grades :

- Outer Diameter :

- Wall Thickness :

- Tube Type :

- Mill Test Certificate(MTC) :

- Certificate :

- Test Content :

- JIS G3463

- 304, 304L, 316, 316L, 309/309S, 310/310S, 321/321H, 347/347H, Duplex2205 / S31803, etc.

- 1/4″ - 8″ / 6.35mm - 203.2mm

- 0.02″ - 0.2″ , 0.5mm - 5mm SCH 5 - SCH 160

- Seamless or Welded

- EN10204 3.1

- ISO 9001:2015 , PED 2014/68/EU , AD 2000-WO

- Flange & Flaring Test,Reverse Flattening Test, Roughness Test, Hydrostatic/Pneumatic Test, Eddy Current Test (NDT), Surface Finish Verification, Dimensional Inspection, Material Certification

| Grade | Chemical composition % | |||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | |

| SUS 304TB | 0.08 max. | 1.00 max. | 2.00max. | 0.040 max. | 0.030 max. | 8.00~11.00 | 18.00~20.00 | – |

| SUS 304HTB | 0.04~0.10 | 0.75 max. | 2.00max. | 0.040 max. | 0.030 max. | 8.00~11.00 | 18.00~20.00 | – |

| SUS 304LTB | 0.030 max. | 1.00 max. | 2.00max. | 0.040 max. | 0.030 max. | 9.00~13.00 | 18.00~20.00 | – |

| SUS 309STB | 0.15 max. | 1.00 max. | 2.00max. | 0.040 max. | 0.030 max. | 12.00~15.00 | 22.00~24.00 | – |

| SUS 310TB | 0.08 max | 1.00 max. | 2.00max. | 0.040 max. | 0.030 max. | 12.00~15.00 | 22.00~24.00 | – |

| SUS 310STB | 0.15 max. | 1.50 max. | 2.00max. | 0.040 max. | 0.030 max. | 19.00~22.00 | 24.00~26.00 | – |

| SUS 316TB | 0.08 max. | 1.50 max. | 2.00max. | 0.040 max. | 0.030 max. | 19.00~22.00 | 24.00~26.00 | – |

| SUS 316HTB | 0.08 max. | 1.00 max. | 2.00max. | 0.040 max. | 0.030 max. | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 |

| SUS 316LTB | 0.04~0.10 | 0.75 max. | 2.00max. | 0.040 max. | 0.030 max. | 11.00~14.00 | 16.00~18.00 | 2.00~3.00 |

| SUS 316TiTB | 0.030 max. | 1.00 max. | 2.00max. | 0.040 max. | 0.030 max. | 12.00~16.00 | 16.00~18.00 | 2.00~3.00 |

| JIS | ASTM/ASME | BS | DIN |

| SA-213 T91 | 17175-X10CrMoVNb91 | ||

| G3463 SUS304TB | SA-213 Tp-304 | 17456 X2CrNi1911 | |

| G3463 SUS304HTB | SA-213 Tp 304H | 3059 CFS304S51 | |

| G3463 SUS316TB | SA-213 Tp 316 | 17456 X5CrNiMo17122 | |

| G3463 SUS316HTB | SA-213 Tp 316H | 3059 CFS316S51 | |

| G3463 SUS321TB | SA-213 Tp 321 | 17456 X6CrNiTi1810 | |

| G3463 SUS321HTB | SA-213 Tp 321H | 3059 CFS321S51 | |

| G3463 SUS347TB | SA-213 Tp 347 | 17456 X5CrNiNB1810 | |

| G3463 SUS347HTB | SA-213 Tp 347H | 3059 CFS347S51 |

Application

Stainless steel tubes are widely used in heat exchangers due to their excellent thermal conductivity, corrosion resistance, and durability. Heat exchangers are critical components in industries such as chemical processing, oil and gas, power generation, HVAC, and refrigeration. Stainless steel tubes are particularly favored for their ability to withstand high temperatures, pressure, and corrosive environments.

- Chemical & Petrochemical Industry

- Oil & Gas Industry

- Power Generation

- Food & Beverage Industry

- HVAC & Refrigeration

- Pharmaceutical & Biotechnology

- Marine & Desalination